MAKE PRECISION FOR YOUR BUSINESS.

Quality of processes and manufacturing, international certifications, flexibility and delivery planning. Attention to detail, product innovation.

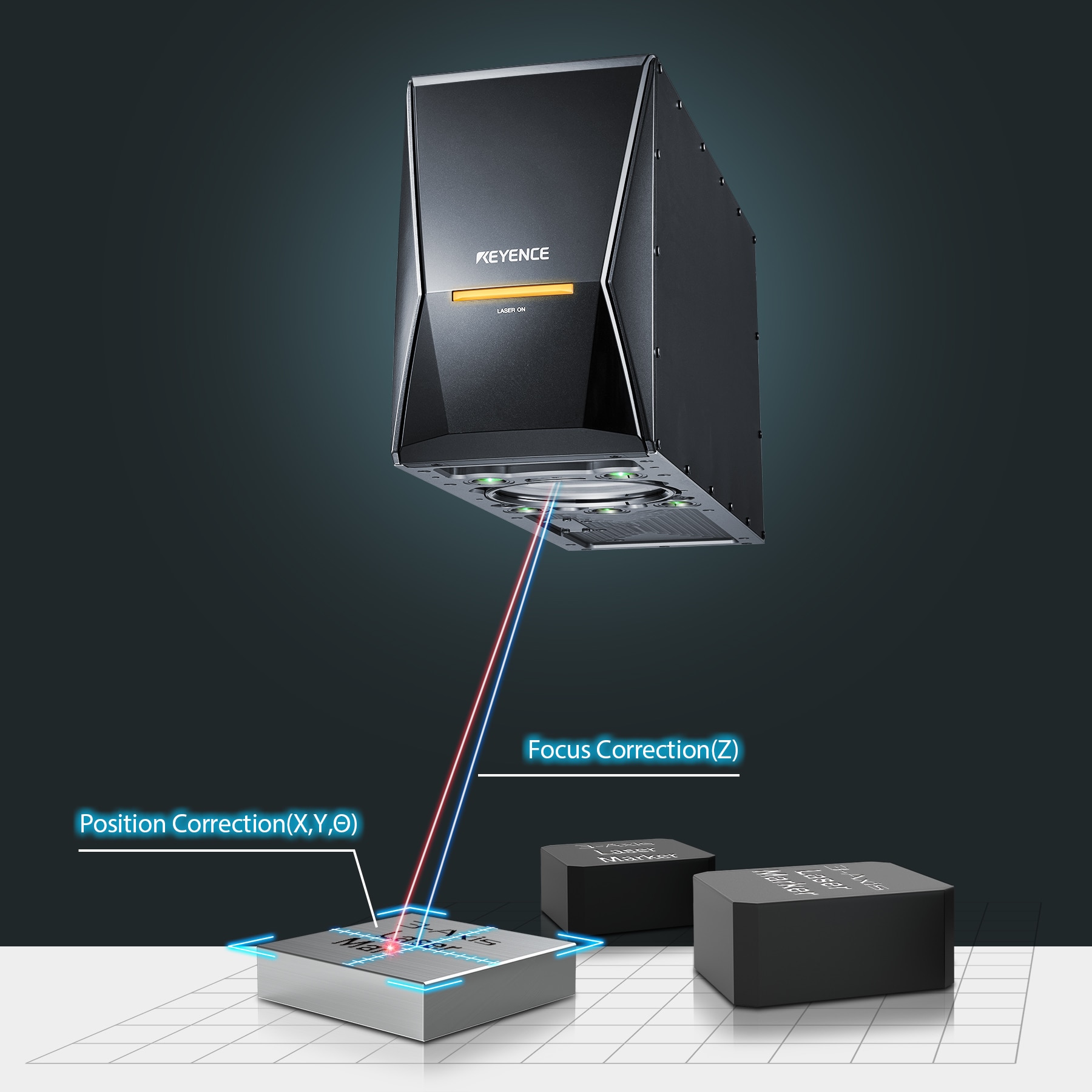

Latest generation machines, highly qualified personnel and a constantly updated production structure. We carry out precision mechanical machining from model engineering to product industrialization in 10 different industrial sectors adapting to every request for production batches.

Dimensional testing and functional suitability certificates, extra certificates.

Statistical control of our production process.

Competence and continuous training of resources.

Industrial

Sectors

International

Markets

Pieces/year

Produced

Years of

Business

The confidentiality of information is a priority for us. We adopt a careful and responsible privacy policy to meet the needs of our customers both in Italy and abroad with international confidentiality agreements NDA.

Uster chooses to carry out precision mechanical machining with a highly competitive service: quality of processes and manufacturing, international certifications, flexibility and delivery planning.

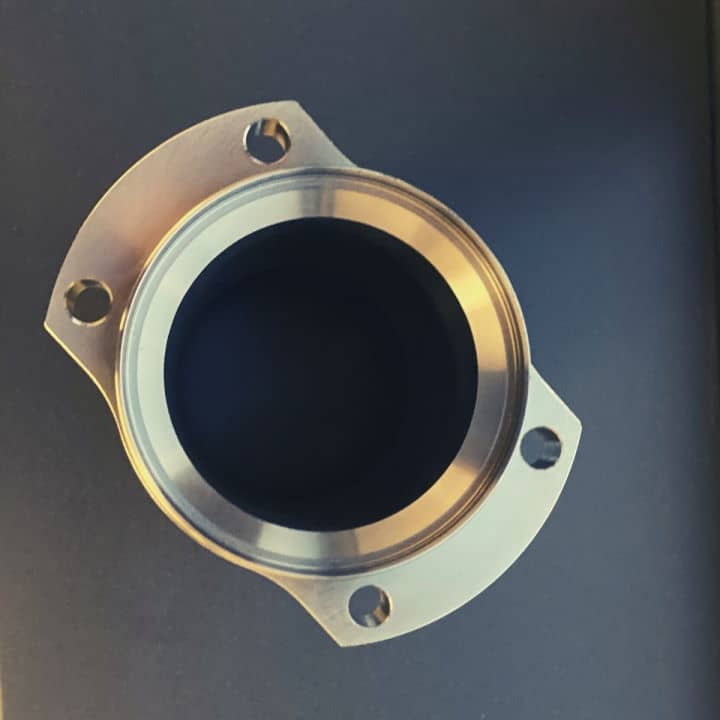

Uster produces components in light alloys, stainless steels, tempered and high quality titanium with high standards in terms of tolerances and surface roughness for 10 industrial sectors.

We program control plans to define a test protocol between customer and supplier. We carry out an in-depth analysis to industrialize the production of the customer's project, evaluating the best technologies in terms of quality and time.

Very high customization and attention to detail of each single component.

• specific quality controls, MOCA and issuing of certificates attesting the non-release of alloying elements on the final product.

• Certificates of dimensional testing and functional suitability.

• Extra certificates: test certificates for assembled groups and quality certificates for single pieces upon customer request, as a further guarantee of the standard controls already foreseen in production. Metrology room, Zeiss "Contura" and "Calypso".

• integrated control of the work progress with planning software MES + APS for the continuous measurements and dimensional statistical checks

• control of production times thanks also to a scheduled maintenance plan of the machinery

• Management system (MRP) to simulate in the order confirmation phase the expected times for processing the production batch.

• Identification of raw materials with QR-Code and unique lots to guarantee delivery dates and urgent requests.

• Kanban warehouse: The Kanban method allows to reduce the lead time necessary for the production of components. Kanban to reduce stocks, optimize the production process and precise delivery planning.

• Integrated tool management: tools always available with automatic magazine.

• Customer specific packaging.

Digital archive of raw material certificates for the safety of origin. Even after many years, the customer can ask for the certificate of a material used for a component.

Each choice generates new opportunities.

We are based in Italy, in Italy, a few kilometers from Treviso and Venice. We are available by e-mail, by telephone, by videocall to fix a possible appointment on site and to give you more information about our products and services.

For more information, visit the Uster website.

About Rois Valves.